In an epoch defined by ceaseless connectivity and the all-encompassing presence of digital diversions, the art of time management has undergone a sophisticated evolution. Cody Moxam, a scholar in the field of psychology, scrutinizes the inventive strategies deployed in an age teeming with digital distractions. He sheds light on the concept of “chrono-hacking,” an avant-garde approach to time management that capitalizes on technology to optimize productivity and foster a healthier relationship with time.

In an epoch defined by ceaseless connectivity and the all-encompassing presence of digital diversions, the art of time management has undergone a sophisticated evolution. Cody Moxam, a scholar in the field of psychology, scrutinizes the inventive strategies deployed in an age teeming with digital distractions. He sheds light on the concept of “chrono-hacking,” an avant-garde approach to time management that capitalizes on technology to optimize productivity and foster a healthier relationship with time.

Traversing the Digital Landscape

Cody Moxam delves into the intricate pathways individuals navigate within the digital landscape to reclaim their time and concentration. The omnipresence of smartphones, social media, and incessant notifications poses challenges to focus and productivity. Responding to this, professionals and individuals alike are now turning to technology not merely as a source of distraction but as a tool to master the art of time management.

Harnessing the Power of Productivity Apps

Productivity apps take center stage in the chrono-hack approach. Cody Moxam explores how individuals leverage the functionalities of apps designed to streamline tasks, organize schedules, and monitor progress. Whether employing project management apps, task trackers, or collaborative platforms, these tools empower users to optimize their workflow, allocate time judiciously, and ensure precise task accomplishment.

Infusing Mindfulness into the Digital Sphere

The amalgamation of mindfulness into the digital realm assumes a pivotal role in chrono-hacking. Cody Moxam observes the indispensable role played by mindfulness apps, crafted to cultivate awareness and sharpen focus, in the quest for effective time management. By incorporating brief meditation sessions, mindful breathing exercises, and periodic breaks, individuals counteract the incessant barrage of digital stimuli, enhancing their ability to concentrate on pivotal tasks.

Digital Well-Being Tools on the Rise

As awareness burgeons regarding the impact of screen time on well-being, Cody Moxam discusses the ascent of digital well-being tools. These tools furnish insights into usage patterns, urging users to set limits on screen time and establish healthier relationships with their devices. By advocating mindful consumption and curtailing unnecessary digital interactions, individuals can reclaim precious time otherwise lost to perpetual scrolling.

The Chrono-Hack Mindset Unveiled

Cody Moxam introduces the chrono-hack mindset as a fundamental paradigm shift in time management. It entails viewing technology not merely as a time-consuming distraction but as a strategic ally in the pursuit of productivity. The chrono-hack mindset encourages individuals to purposefully embrace digital tools, utilizing them to augment efficiency and create a focused work environment.

Cultivating a Harmonious Relationship with Time

The ultimate objective of the chrono-hack approach is to foster a more harmonious relationship with time. Cody Moxam explores how individuals, armed with digital tools and a chrono-hack mindset, can regain mastery over their schedules, alleviate stress, and attain an improved work-life balance. By considering technology as an accomplice in the journey towards effective time management, individuals can navigate the intricacies of the digital age with assurance and purpose.

Students in rural areas without reliable access to

Students in rural areas without reliable access to

If you live in rural America, you may be wondering how to get the fastest possible

If you live in rural America, you may be wondering how to get the fastest possible

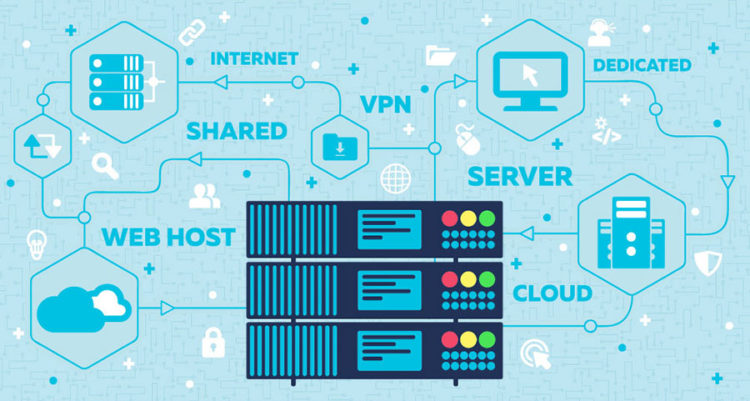

Hosting your own website might sound like a lot of work and relatively advanced for people who are outside the industry. End of the day, owning a business in Los Angeles takes a lot of time, so you need to find a company to host your website for you. This will ensure you can focus on the parts of your business you are good at.

Hosting your own website might sound like a lot of work and relatively advanced for people who are outside the industry. End of the day, owning a business in Los Angeles takes a lot of time, so you need to find a company to host your website for you. This will ensure you can focus on the parts of your business you are good at.

Many factors can influence which provider you pick from the

Many factors can influence which provider you pick from the

Blog provided by

Blog provided by

As technology has advanced throughout the decades, different fields of business and commerce have found novel, inventive ways to use technology to boost productivity. Here are a few modern innovations that your business might use to stay ahead of the competition.

As technology has advanced throughout the decades, different fields of business and commerce have found novel, inventive ways to use technology to boost productivity. Here are a few modern innovations that your business might use to stay ahead of the competition.